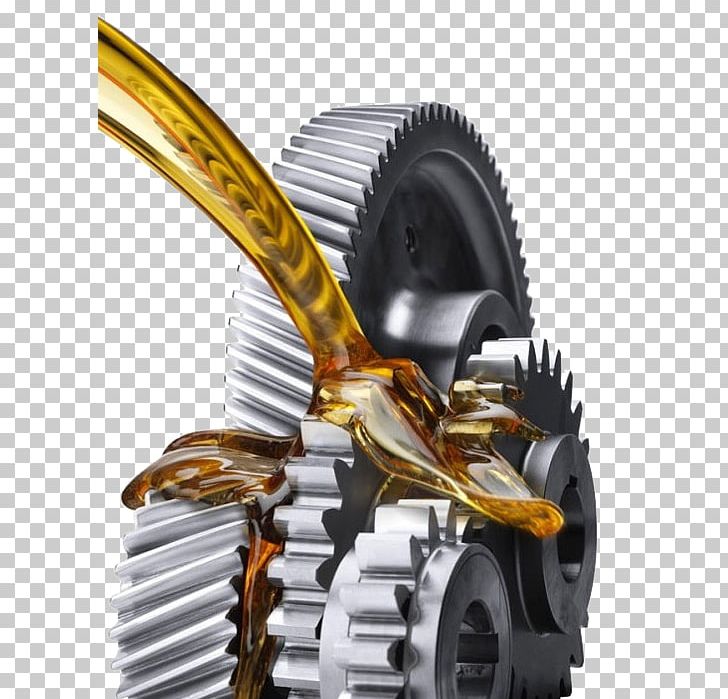

How Are Engine Oil Lubricants Made?

Lubes, liquids and even water are being used for lubrication purposes since the Roman era, to reduce friction, minimize heat and stiffness, dispense deposits and clean up the engine or sliding metallic parts. Today, there are way more application scenarios for these lubricants and lubricating brands, not just in the automotive sector, but in almost every industry involving machines and different sorts of engines. The point of concern here is, how are these engine oil lubricants made? Let’s dig up the answer to this concern and feed the natural curious insights of human beings. Engine oil lubricants are mainly tiny components of raw petroleum that is extracted out of the Earth’s crust in yellowish or blackish colored crude oil. This crude oil is a liquid mixture of thousands of hydrocarbons that are extracted and separated at specific temperatures through the fractional distillation process. At first, the lube oil, extracted out of the crude oil, is bound to undergo the purification process, which is termed as Sedimentation. This Sedimentation process involves the removal of water and solid contaminants, such as sand and rocks that are the reason for its polluted and colored texture.

Fractionating towers

The next step involves fractionating towers, where this crude oil is heated to about 700 degrees Fahrenheit (370 degrees Celsius), to break down its formation and turn it into a mixture of hot vapors and liquid. These are then pumped towards the bottom of the fractionating tower where on cooling, various hydrocarbons with different specifications are collected at different trays inside the vertical length of the fractionating tower. Through this process, 80% of this crude oil is broke down into its final products. The remaining 20% is then forwarded towards the second fractionating tower whereby applying vacuum pressure, boiling points are lowered and vapors are made at comparatively less temperature. This way, more components are collected at different temperatures and heavier ones are left as residuals for further processing.Filtration and Solvent Extraction

The next step involves Filtration and Solvent Extraction, which involves ultrafine filters to purify the lube oils extracted during the fractionating process and impurities are removed. This step also involves solvent mixing which dissolves some impurities like Aromatics, which are easily collected after the solvent is extracted out and left one will be then the pure lube oil. This process is specially designed to improve the quality of lubricating oils and improve their usability in different industries according to the requirements of the engines.Mixing Additives

The last step in this manufacturing process involves mixing Additives, Inspection and then Packaging the lubricants for commercial use. Lubricant oils are mixed with additives to improve their usability and add more features to them so as to enhance their durability and sustainability with the workload, as well as, engine clean up and deposits removal. Then this lubricant oil is inspected through quality control tests to verify its commercial use and quality standards, as well as, global quality indexes. The last step involves packaging these qualities assured lubricant oil for commercial use and sustain our engines at long and perform better.Comments are closed.